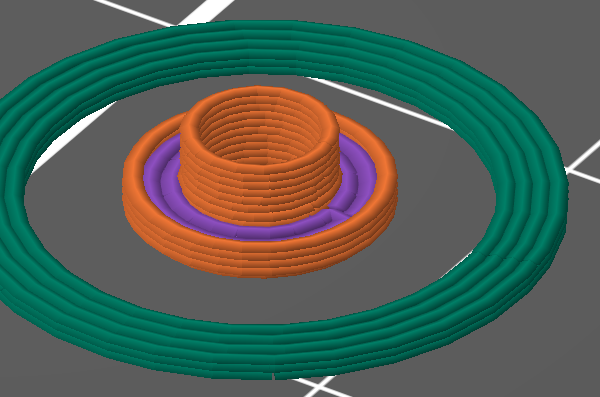

Your outer diameter is accurate to ¼ of an extrusion width and the inner to ½ which is pretty good for an extruded line.

(3.5-2.7)/2 = 0.4mm wall thickness. The default extrusion width with a 0.4mm nozzle is 0.45mm so you might want to redesign, especially as reduced extrusions will be weaker. Yes, there are ways to tune the extrusion but with such small parts and tolerances it will not be easy and is unlikely to be satisfactory.

Which CAD software are you using?

Most CAD calculates points on the midline of a curve and then connects the dots when converting to STL – so all curves are in fact a series of chords and will always reduce towards the concave side. As a first approximation of a multi-extrusion thick cylinder you should offset the critical radii by half an extrusion width so the spread of the extrusion fills in the diffference. With just one extrusion you are stuck with just one midline. Your CAD may have an accuracy or detail setting which will reduce the effect or if it can output to STEP files instead you may gain some accuracy that way.

As the part is so small you may as well print a few different sized calibration parts and home in on the best fit available.

Cheerio,